If you’re involved in the automotive industry, whether you manage a fleet of vehicles or are simply a car enthusiast, understanding fuel options is crucial. Beyond traditional diesel, biodiesel has emerged as a notable alternative. This article from keyfobx.com, your trusted auto repair resource, delves into a detailed comparison of biodiesel and diesel fuel. We’ll explore their compositions, environmental impacts, engine compatibility, performance metrics, and costs to provide you with a comprehensive understanding. Whether you’re considering switching to biodiesel or simply want to be more informed, this guide will equip you with the knowledge to make the best decision for your needs.

Decoding Biodiesel: A Cleaner Fuel Alternative

Biodiesel is recognized as a cleaner-burning substitute for conventional petroleum diesel. As one of the earliest biofuels, it’s produced through a process called transesterification. This process transforms natural oils and fats into a fuel suitable for diesel engines. Pure biodiesel, known as B100, is entirely composed of biodiesel and contains no petroleum diesel.

Biodiesel originates from renewable sources, including vegetable oils (like soybean, sunflower, palm, and rapeseed oil), recycled cooking grease, algae, and animal fats. In the United States, soybean oil is the primary feedstock for biodiesel production.

A significant advantage of biodiesel is its reduced environmental footprint. When comparing biodiesel fuel vs. diesel, biodiesel stands out due to its lower carbon monoxide emissions. This is because biodiesel contains 10% to 12% more oxygen than petroleum diesel. This higher oxygen content contributes to a more complete combustion process, resulting in fewer harmful emissions and particulate matter compared to traditional diesel.

Diesel vs. Biodiesel: Dissecting the Differences

While both fuels power diesel engines, diesel and biodiesel differ significantly in their composition and environmental impact. Diesel fuel is a petroleum-based product derived from crude oil and biomass sources through refining. In contrast, biodiesel is made from renewable biological sources like plant and animal fats.

Traditional diesel fuel contains benzene, a known carcinogen, and sulfur. Burning diesel releases pollutants such as sulfur oxides, carbon monoxide, nitrogen oxides, and particulate matter, which negatively impact both the environment and human health.

Recognizing these environmental concerns, the Environmental Protection Agency (EPA) mandated regulations in 2006 to reduce emissions, specifically targeting the sulfur content in diesel fuel. Today, ultra-low sulfur diesel (ULSD) is the standard for on-road vehicles in the U.S.

Despite the improvements in diesel fuel, key differences remain between diesel and biodiesel across several critical factors:

1. Engine Compatibility: Biodiesel in Your Diesel Engine

Modern diesel engines are generally designed to run on biodiesel blends with little to no modifications. However, older diesel vehicles might require adjustments for optimal biodiesel use. Biodiesel can degrade rubber components, so older trucks might need their seals, gaskets, and fuel lines replaced with biodiesel-compatible materials.

biodiesel vs diesel engine compatibility

biodiesel vs diesel engine compatibility

Upgrading diesel engine components to be biodiesel-compatible often involves switching rubber seals and hoses to polyurethane, a more durable and flexible material. Thermoplastic elastomers can also be used for gaskets and seals to prevent leaks.

In contrast, traditional diesel engines are engineered specifically for petroleum diesel fuel. Diesel has been the standard fuel for trucks for decades, predating the widespread availability of biofuels.

Using Biodiesel in Diesel Engines:

Biodiesel can be used in most modern diesel engines, either as pure B100 or blended with petroleum diesel in various ratios. Engine manufacturers (OEMs) generally approve the use of biodiesel blends because biodiesel engines utilize the same combustion technology as traditional diesel engines.

Common biodiesel blends include B20 (6%-20% biodiesel with petroleum diesel) and B5 (5% biodiesel, 95% diesel). These blends enhance fuel lubricity and increase the cetane number, leading to improved engine starts and smoother operation.

While biodiesel blends are generally safe for diesel trucks, it’s always recommended to check your engine warranty, especially for older vehicles, to confirm biodiesel compatibility.

Diesel Number Two and Biodiesel:

Diesel number two is a grade of petroleum diesel and not a type of biodiesel. It is frequently blended with biodiesel to create fuels like B5 and B20. Diesel number two is commonly used in heavy-duty trucking.

A significant difference arises in cold weather performance. Diesel number two performs well in winter conditions, whereas biodiesel is susceptible to gelling at low temperatures, potentially affecting vehicle operation in cold climates.

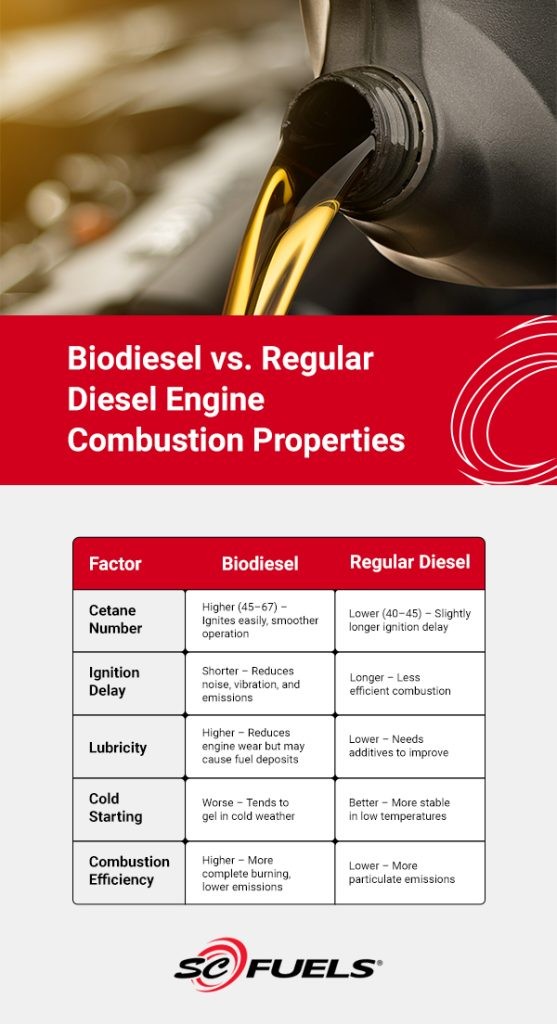

2. Engine Combustion Properties: How They Burn

Engine combustion performance and efficiency are influenced by several factors when comparing biodiesel and diesel fuel:

- Cetane Number: Biodiesel typically exhibits a higher cetane number (45-67) compared to diesel fuel (40-45). A higher cetane number indicates easier fuel ignition, resulting in enhanced power, smoother engine operation, and reduced emissions.

- Ignition Delay: Due to its higher cetane number, biodiesel tends to have a shorter ignition delay – the time between fuel injection and combustion. This leads to more efficient combustion, reducing engine noise, vibration, and smoke, ultimately improving engine reliability.

- Lubricity: Lubricity refers to a fuel’s ability to reduce friction between engine components, crucial for minimizing wear in diesel engines. Biodiesel improves lubricity compared to regular diesel. Even a small percentage of biodiesel (around 2%) can significantly enhance lubricity and extend engine life. However, high lubricity can also lead to fuel deposits that may clog filters, requiring more frequent filter changes.

- Cold Starting: While a higher cetane number generally aids cold starting, pure biodiesel and high biodiesel blends are more prone to gelling in cold weather than diesel. This crystallization at low temperatures can be a concern in extremely cold climates.

- Combustion Efficiency: Biodiesel generally offers better combustion efficiency than diesel fuel, resulting in more complete burning within the engine’s combustion chamber. This leads to reduced particulate emissions and improved overall engine performance.

3. Emissions Comparison: Environmental Impact

Biodiesel and diesel differ significantly in their life cycle emissions and environmental impact. While both produce carbon dioxide (CO2) when burned, biodiesel’s CO2 emissions are partially offset by the CO2 absorbed by the plants (like soybeans) used to produce it. This results in a substantial reduction in net CO2 emissions over its life cycle.

The U.S. Department of Energy indicates that pure biodiesel (B100) reduces emissions by 74% compared to diesel. A B20 blend achieves approximately a 15% reduction in CO2 emissions.

Beyond CO2, biodiesel also shows advantages in other emissions:

- Carbon Monoxide (CO): Biodiesel produces significantly lower CO emissions than diesel.

- Hydrocarbons (HC): Diesel generates higher hydrocarbon emissions, suggesting biodiesel burns more cleanly.

- Nitrogen Oxides (NOx): Pure biodiesel may produce slightly higher NOx emissions than diesel. However, modern diesel vehicles (post-2010) equipped with selective catalytic reduction (SCR) technology effectively mitigate NOx emissions by converting them into water vapor and harmless nitrogen.

4. Fuel Efficiency: Diesel vs. Biodiesel

Diesel fuel contains more energy per gallon than biodiesel. This higher energy density translates to greater fuel efficiency, allowing vehicles to travel farther on a single tank. Diesel engines, especially modern ones with advanced electronic controls and fuel injection systems, are highly fuel-efficient. Petroleum diesel is generally 10% to 15% more fuel-efficient than gasoline.

In contrast, B100 biodiesel exhibits about 10% lower fuel efficiency compared to diesel. However, using a B20 blend reduces this difference to approximately 2% less fuel efficiency than diesel. While biodiesel might lead to slightly higher fuel consumption, especially at higher blends like B100, it remains a more sustainable and less polluting fuel choice overall.

Government Support for Biofuel Production:

Government incentives and policies play a crucial role in supporting biofuel production and bridging the cost gap with traditional fuels. Federal biodiesel laws and programs encourage the development of advanced biofuels and aim to reduce production costs.

For instance, the USDA Biomass Crop Assistance Program assists landowners in growing biomass feedstock crops for biofuel production by offering financial reimbursements and matching payments. These initiatives promote domestic biofuel production and reduce reliance on imported fuels.

As petroleum fuel prices rise and environmental regulations become stricter, biodiesel presents a sustainable and potentially more economical fuel option in the long run. Its production also supports local economies and reduces dependence on foreign oil.

5. Fuel Cost Comparison: Biofuel vs. Diesel

The cost of biodiesel and diesel fluctuates based on region, taxes, blend, and other market factors. Pure B100 biodiesel generally tends to be more expensive than diesel, while B20 blends are often priced competitively, sometimes even lower than conventional diesel.

Analyzing national fuel price averages from October 1-15, 2024, B100 was priced at $4.04 per gallon, B20 at $3.53, and diesel at $3.64 per gallon. These figures are indicative and can change.

Diesel prices are influenced by standard fuel market factors like taxes, regulations, refining costs, distribution, and marketing. Biodiesel prices are affected by feedstock availability and state-specific incentives.

For example, the biodiesel income tax credit, which ended in January 2025, incentivized biodiesel production and use by offering taxpayers a $1 per gallon credit for using biodiesel in their business or delivering pure biodiesel. This policy aimed to support domestic biodiesel producers and enhance market accessibility.

Biodiesel Supply and Price:

Limited biodiesel supply compared to diesel can drive up biodiesel prices. Without supportive tax incentives, domestic biodiesel producers might face challenges in offering competitive prices, especially if they rely on imports to meet demand. Higher import tariffs and production costs in exporting countries can further increase biodiesel prices.

Consequently, in situations of biodiesel scarcity, diesel may become a more readily available and practical fuel choice, particularly for large trucking fleets.

Biodiesel vs. Renewable Diesel: Key Differences

Biodiesel and renewable diesel are both sustainable alternatives to petroleum diesel, but they differ significantly in their production methods and fuel properties. Biodiesel is produced through transesterification. It has a higher freezing point, is prone to gelling in cold weather, and cannot be transported via pipelines in its pure form.

Renewable diesel, on the other hand, is produced through hydrotreating. This process yields a cleaner, pure fuel that is chemically very similar to petroleum diesel. Renewable diesel is highly compatible with existing diesel engines, offering reliable performance and fewer engine-related issues. It boasts a higher energy density than biodiesel, leading to improved fuel efficiency and potentially lower fuel consumption over time.

Furthermore, renewable diesel can be transported through pipelines and stored alongside fossil fuels. It also has a lower freezing point than biodiesel, making it more suitable for cold climates. However, renewable diesel production is more complex and requires higher-quality feedstocks, typically making it more expensive than biodiesel.

Conclusion: Making the Right Fuel Choice

Choosing between biodiesel and diesel fuel involves weighing various factors, including environmental concerns, engine compatibility, performance needs, and cost considerations. Biodiesel offers a more sustainable and cleaner-burning alternative with reduced greenhouse gas emissions and improved air quality. While it might have slightly lower fuel efficiency and potential cold weather limitations, advancements in biodiesel blends and engine technology are continuously mitigating these drawbacks.

For businesses seeking to reduce their carbon footprint and support renewable fuel sources, biodiesel presents a compelling option. Understanding the nuances of biodiesel fuel vs. diesel empowers you to make informed decisions that align with your operational needs and sustainability goals.

For reliable fuel delivery services, including biodiesel and renewable diesel, consider partnering with established providers like SC Fuels. They offer a range of fuel solutions to meet diverse business requirements.

[